We are happy and proud to share our annual wrap-up blog with you.

A quick recap, in 2022 we:

Went from 250 to 800+ devices sold;

Grew from 15 to 60+ clients;

Went from having distributors in 3 countries to 7;

Were granted 5 global patents;

Grew from 30 to 100+ employees from 17 different nationalities, located in 3 different countries to serve our clients better;

Secured a new investment round of ~$25M from world-class investors;

10x better performance in our Artificial Intelligence inspection software (also added new defect detection such as irregular yarns, some mini-jacquards & auto-stripers machines);

UV light inspection for better results on yarn contaminations, barrié effects, etc;

Created a dedicated 24/7 Technical Support team

💡 Some major lessons from 2022:

The textile industry is more challenging than ever — gross margins are always tight, and we are noticing increased production requirements (performance, quality, sustainability, traceability, etc) — these trends are here to stay, and we need to adapt and embrace them.

We see a big shift in the world towards automation — industry 4.0, zero room for mistakes or quality problems — 1 kg of rejected fabrics might imply a production of 10 or 20 kg of good fabrics — that’s a big challenge!

Quality Control is becoming even more complex — many defects are subjective, clients are getting pickier, and it’s difficult (sometimes impossible) to calculate the real defective percentage because it depends on future variables such as the cut map on the cutting table) — however, this % can be crucial for our clients’ business health.

Quality Control is related to all departments — by fully understanding the quality of their products, our clients can know about the quality of your suppliers, machines, workers, production, and much more. We are glad to see many of them using our Online Platform to start changing internal processes. This is just the beginning!

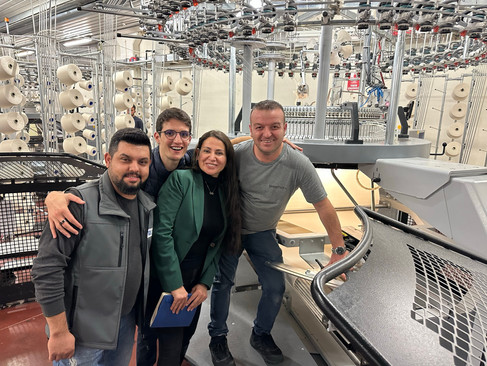

👏 Main customer highlights for 2022:

⭐ In general, every Smartex customer is a leader — this digitization of the industry is not a wave, but a tide — they have the vision for the future of textiles, and therefore they will be stronger — innovation always wins — congrats to all our clients for leading the next generation of textile factories 👌.

📽️ Our first customer video case studies of 2022 were with HATA and Ekoten.

💯% Production with Smartex — congratulations to Merboy Tekstil and Nero for achieving this important milestone! These companies are now ready to provide 100% assurance to their clients that everything is inspected and photographed, with provable value that is easier to track.

🔝 Our top 3 clients right now are:

MEM Tekstil with 100 devices

Toraman with 88 devices

Kasar & Dual with 63 devices

What’s next for 2023?

👊 Please keep pushing us! No one knows better than our clients how we can develop further.

👉 Follow us — on all platforms (LinkedIn, Instagram, Facebook, Twitter) to keep updated on our product launches, special features, case studies and educational materials — we also count on meeting all our clients at ITMA 2023 where we have special announcements to make! 🤞

Our goal is to build the textile factory of the future: one that is connected, with production that is easily monitored, machines that operate at peak performance, and on a path towards a zero-waste digital future. We will continue to invest in R&D to deliver a better user experience for our customers and to build solutions that add value to the industry.

On behalf of the Smartex, we'd like to thank you for your support.

We wish you a phenomenal 2023!